Ultimate Comparison Guide: Solvent vs. Eco-Solvent vs. Latex vs. UV Lamination Films

Ultimate Comparison Guide: Solvent vs. Eco-Solvent vs. Latex vs. UV Lamination Films

When it comes to choosing the right lamination film for your printed media, the ink type plays a crucial role. Not all films are compatible with every ink, and understanding the difference between solvent, eco-solvent, latex, and UV lamination films helps ensure the durability, clarity, and quality of your final product. In this ultimate comparison guide, we’ll break down each type, its pros and cons, and where each excels.

1. Understanding Lamination Films

Lamination films protect printed graphics from environmental elements like UV rays, moisture, scratches, and pollution. They also enhance aesthetic appeal by adding finishes such as gloss, matte, or textured effects. However, the adhesive chemistry and film construction must match the ink technology used during printing.

2. Solvent Lamination Films

Solvent lamination films are designed to pair with solvent-based inks. These inks are aggressive and penetrate the media surface, which makes them durable and waterproof.

Key Features:

- High compatibility with aggressive solvent inks

- Strong adhesive bond

- Excellent outdoor durability

Pros:

- UV resistant and waterproof

- Long-lasting in outdoor environments

- High ink adhesion

Cons:

- Typically not eco-friendly

- Emits strong fumes during application

Best Used For:

- Outdoor signage

- Vehicle wraps

- Industrial graphics

3. Eco-Solvent Lamination Films

Eco-solvent lamination films are optimized for prints using eco-solvent inks, which are less aggressive and more environmentally friendly than traditional solvent inks.

Key Features:

- Lower VOC emissions

- Softer ink adhesion layer

- Good outdoor durability

Pros:

- Reduced environmental impact

- Safer for indoor use

- Reasonable outdoor performance

Cons:

- Slightly less durable than solvent counterparts

- Requires compatible surface energy for bonding

Best Used For:

- Indoor/outdoor advertising

- Wall graphics

- Posters and displays

4. Latex Lamination Films

Latex-compatible lamination films are engineered to work with water-based latex inks. These inks sit on the media surface and require films with adhesives that can bond to a cured ink layer.

Key Features:

- Water-based adhesive systems

- High clarity and flexibility

- Environmentally friendly

Pros:

- Low VOCs and odorless

- Immediate post-print lamination (no gassing out needed)

- Excellent color vibrancy

Cons:

- More expensive

- Sensitive to heat and pressure variations

Best Used For:

- Wall coverings

- Fleet graphics

- Retail signage

5. UV Lamination Films

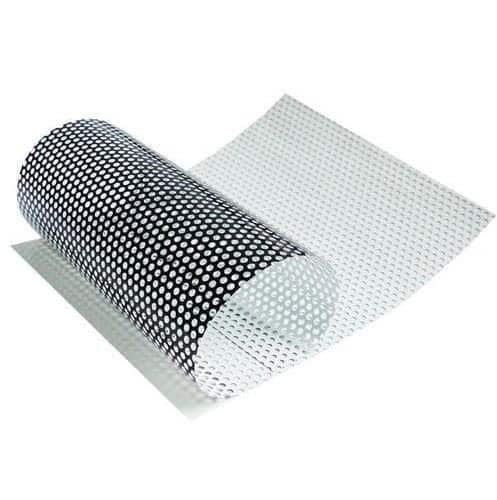

UV-compatible lamination films are specifically tailored to bond with UV-cured inks, which form a hard surface upon curing with ultraviolet light.

Key Features:

- High-tack adhesive formulations

- Often require textured films for better grip

- Designed for rigid surfaces

Pros:

- Excellent for flatbed printed graphics

- Scratch and chemical resistant

- Durable and high-gloss finishes

Cons:

- Inflexible—unsuitable for wrapping

- May crack on flexible substrates

Best Used For:

- POP displays

- Trade show graphics

- Rigid signage

6. Key Comparison Table

| Feature | Solvent Films | Eco-Solvent Films | Latex Films | UV Films |

| Durability (Outdoor) | High | Medium-High | High | High |

| Eco-friendliness | Low | Medium | High | Medium |

| Print Compatibility | Solvent inks | Eco-solvent inks | Latex inks | UV inks |

| Flexibility | High | Medium | High | Low |

| Cost | Medium | Medium | High | Medium |

| Ideal Use | Vehicle wraps, signs | Indoor/outdoor graphics | Wall decor, displays | Rigid POP displays |

7. How to Choose the Right Lamination Film

- Identify Your Ink Type: Always start with the printing technology—matching ink and lamination chemistry is essential.

- Consider Application Environment: Outdoor or indoor? Rigid or flexible? High traffic area?

- Think About Finish and Feel: Do you want glossy, matte, or textured? Does the film need to be anti-glare or scratch-resistant?

- Evaluate Cost vs. Performance: Some high-end films cost more but offer better durability and ease of use.

PaperLam’s Expertise

At PaperLam, we understand the science behind film performance. Our lamination films are rigorously tested to work seamlessly with a range of ink technologies, ensuring adhesion, clarity, and protection. We offer specialized solutions tailored for solvent, eco-solvent, latex, and UV applications—helping brands deliver results that last.

Choosing the right lamination film is more than a finishing touch—it’s a commitment to performance, presentation, and longevity. Whether you’re wrapping a fleet of vehicles or installing point-of-sale graphics, the right pairing between your ink and lamination ensures maximum value and impact. Need help choosing? PaperLam’s experts are here to guide you.